The 2004 film “Napoleon Dynamite” featured a scene with a drawing of a hybrid beast the titular character called a “Liger,” a cross between a lion and a tiger. Courtney Boice of Utah-based Blue Halo decided it would be a fitting name for the new series of hybrid-construction fly rods that will be released in the coming weeks.

Boice has developed a new fabrication process using carbon fiber and fiberglass to produce the blanks — the core of the rod where hardware is attached. The recipe is the only of its kind and one Boice is not keen to share with the public. Eight different models will be offered under the Liger name.

Carbon fiber has been the predominant material of choice in modern fly rod construction. However, recent years have seen a resurgence in fiberglass fly rod growth. Several mainstream fly fishing companies have embraced the slower action of fiberglass and have been growing their product lines to include fiberglass offerings.

Carbon fiber, or graphite, as it is often referred to, is a unique material for fly rods as the material has a higher elastic modulus. Specifically, Young’s modulus measures a ratio of tensile stress over tensile strain to determine deformation along the axis of the material with the application of opposing forces along that axis.

To the layperson, this means higher modulus equates to a stiffer material. Carbon fiber rods have a higher modulus than fiberglass rods. The stiffer flex requires more energy to cast and doesn’t often bend below the upper half of the rod. The casting stroke must also be faster than with a lower modulus rod.

The lower modulus of fiberglass “loads” easier, meaning it bends farther down toward the handle. The action of the casting stroke is much slower than with a carbon fiber rod due to the slower line speed.

Both materials excel in certain aspects but have shortcomings in other areas. Carbon fiber rods achieve higher line speeds and are good for large flies and long casts, typically difficult with slower rods. That fast action makes a sacrifice in presentation of the fly on the water, though, and typically don’t make delicate casts as well as fiberglass rods.

Fiberglass is better for the health of the fish’s jaw structure because of the cushioning action of the rod. “Glass is a big shock absorber. It’s better for fish fighting and landing,” Boice explained describing the effect of the head shaking, running and jumping of fish when an angler hooks up.

Finding a rod that is “just right” is a bit of a Goldilocks principle. Boice has attempted to attain that elusive condition with the Liger series of rods.

“Nobody is doing what we’re doing now,” said Boice. “We’ll view this as our contribution to the fly fishing market.” The development of the Liger rods took more than two years.

Boice describes Blue Halo’s place in the outdoor industry as a niche within a niche. Blue Halo previously sold reels and nets in addition to their fiberglass rods and blanks. Boice felt that the company was spread too thin. “We did too much, so we backed off and did what we do best: rods,” Boice said.

Blue Halo has released two generations of rod designs before the Liger. These first two generations were three-piece fiberglass blanks. Ahead of the release of the Liger, the third iteration of the colorful fiberglass blanks and rods will be in a four-piece configuration. An addition of two new models expands the series to five different line weights.

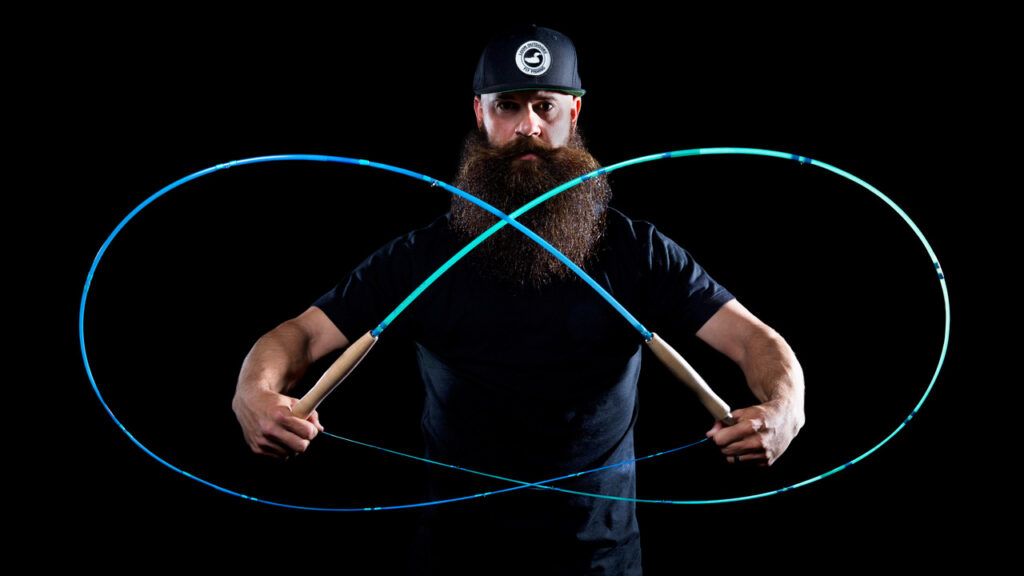

The fiberglass rods are translucent and allow the angler to view any imperfections in the material and when held up to light appear to glow.

Next year, Boice plans to release a “Big Game” series of rods. These rods will be constructed with structural fiberglass, commonly referred to as S Glass. This fiberglass is unidirectional and has a slightly higher modulus than electrical glass, or E Glass that is a cross directional weave. The S Glass will make longer casts, especially into wind, easier, and offer more lifting power for larger fish.